Product Description

Fiber Closure Vertical type 24 Cores Splice Tray 2 IN 2 OUT Hot melt sealing

The SPFC-NV-XXH-2-2A series Dome Fiber Optic Splice Closure is used in aerial,wall-mounting applications,for the straight-through and branching splice of the fiber cable.The closure has four entrance ports on the end (three round ports and one oval port ). The box body and the base are sealed with the silicone rubber. The cable seal is sealed with a heat shrinkable tube.The box suitable for Ф 7 -Ф 22 cable in and out.

Features

● The fiber optic splice closure consists of cover,pedestal,splice tray,hoop,optical cable storage box,single fiber splice tray. The maximum capacity 24 cores per tray

● This is single fiber splice closure, it provide with one elliptical port and 3 round ports.The elliptical port, which can hold two stick optical cables.

● The cable entry ports are sealed with heat shrinkable tube.

● The product are available for aerial,underground, duct-mounting .

● The case body is made from imported high-intensity engineering plastics(MPP) and formed the shape with mould plastics under high pressure.with the advantages of less weight, high mechanical intensity, corrosive-resistance, anti-thunderstruck and long service life.

● Equipped with air - core and installation

| Item |

Parameter |

| Type |

SPFC-NV-XXH-2-2A |

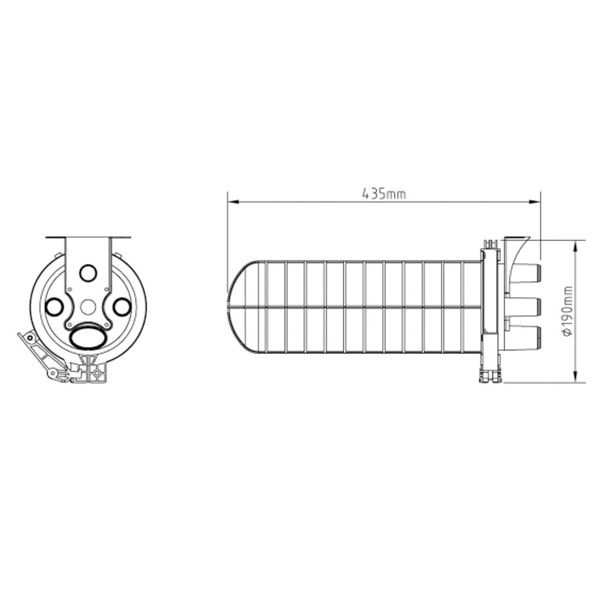

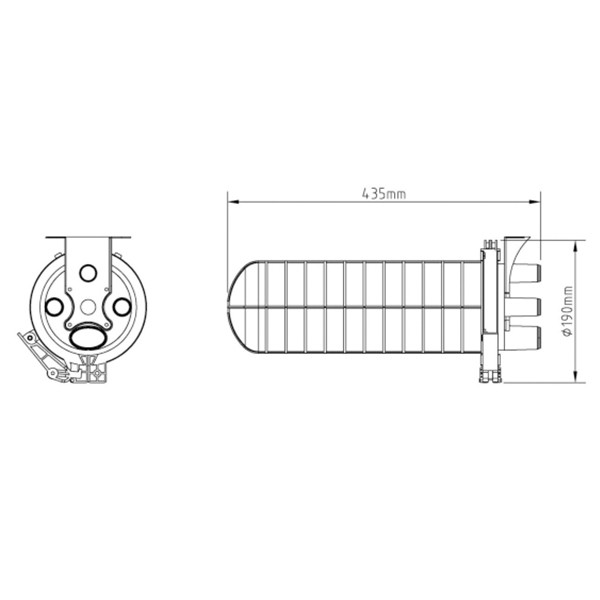

| External Size |

Φ190×435mm |

| Net weight |

2.5kg |

| Cable ports |

One elliptical port and 3round ports. |

| Way to install |

Pole-mounting /Wall-mounting/Aerial installation; Wall-mounting

|

| Cable diameter |

Φ7~Φ22 |

| Capacity of splice tray |

24 single fiber |

| Sealing structure |

Heat shrinkable sealing structure silicon gum material |

| Max. Number of Trays |

4 |

| Max Capacity |

96 single fiber |

| Work Temperature |

-40 °C ~+60°C |

| Voltage resistance strength |

15 kv dc, 1 minute no breakdown, no flash over phenomenon. |

| Insulation resistance |

≥2×104MΩ

|

| Tensile force |

≥800N |

| Sealing |

inflatable make the internal pressure of 100 kpa, into the water to observe more than 15 min, airless bubble generation, air pressure is not falling. |

| Impact strength |

impact energy under16N.m, impact times for 3 times, no cracks |

Operations

I,optical cable installation

1.saw the entry port for easy inserting the optical cable.

2.clean the dust and other stains on the optical cable(about 1.8m) with clean cloth.

3.insert the optical cable into entry port

II,optical cable preparation

1. strip the protective sheath of optical cable, clean the fillings on the loose tube, cut off reinforced core which 75mm away from the sheath slice.

2. cut loose tube ,which 35mm away from the cable slices, clean the grease on the optic fiber, insert the fiber into the exposed wire protective sleeve.

3.insert reinforced core into reinforced core fixing screws, and press it tightly, cut off surplus part.

III,elliptical port sealing

1.clean the elliptical port and protective sheath with paper or cloth.

2.abrade the elliptical port and protective sheath,then clean the leavings.

3.put heat shrinkable tube 3(b) on the elliptical port,then paste a mark on the optical cable which on bot tom of the tube.

4.paste another mark 5mm away from the first mark

5.wind the heat alumimun screen around the optical fiber from the second mark.

6.when install second optical cable, please choose heat shrinkable tube according to the size of cable and insert branch card. (remarks: insert all branch card into heat shrinkable tube)

7.heat the shrinkable tube, until the mucus sliding from the two cables.

IV,optic fiber installation

1.every splice tray can hold maximum 24 fibers, the margin of the tray can hold 2 sticks exposed fiber protective sleeve,

2.cut off surplus protection sleeve,and fix the protection sleeve on the fiber splice tray with

nylon tie.

V,optic fiber connecting and storage.(picture 4

1.connect optic fiber according to the connection requirements.

2.set the splices in the tray grooves, surplus fibers coiled in the tray.

3.check the fibers,and put transparent cover on ,fix it on the splice tray.

VI,splice closure installation

1.put the cover on the pedestal and seal them with hoop

2.pole-mounting please choose accessories 1 and 9

3.wall-mounting please choose accessories 13

Ordering Information

| Model No. |

Description |

Size |

Package |

Weight/ carton |

| SPFC-NV-24H-2/2A |

Fiber Closure Vertical type 24 Cores Max , 24 Cores Splice Tray 2 IN 2 OUT Hot melt sealing type A |

Φ190×435mm |

550*450*480/6PCS |

15KG/6PCS |

| SPFC-NV-48H-2/2A |

Fiber Closure Vertical type 48 Cores Max , 24 Cores Splice Tray 2 IN 2 OUT Hot melt sealing type A |

Φ190×435mm |

| SPFC-NV-72H-2/2A |

Fiber Closure Vertical type 72 Cores Max , 24 Cores Splice Tray 2 IN 2 OUT Hot melt sealing type A |

Φ190×435mm |

| SPFC-NV-96H-2/2A |

Fiber Closure Vertical type 96 Cores Max , 24 Cores Splice Tray 2 IN 2 OUT Hot melt sealing type A |

Φ190×435mm |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!